Automation in the Crane and Materials Handling Industry

- Oct 6, 2025

- 6 min read

Industry Trends and Automation

What specific automation technologies are currently being adopted in the crane and materials handling industry by igus? Igus is actively introducing various automation technologies to the crane and materials handling industry.

Robotics and Automated Systems

igus offers automation solutions like the robolink® modular robotic arms, which can be integrated into materials handling processes for tasks such as sorting, packaging, or assembly. Our solutions are lightweight, low maintenance, and designed for cost effective automation.

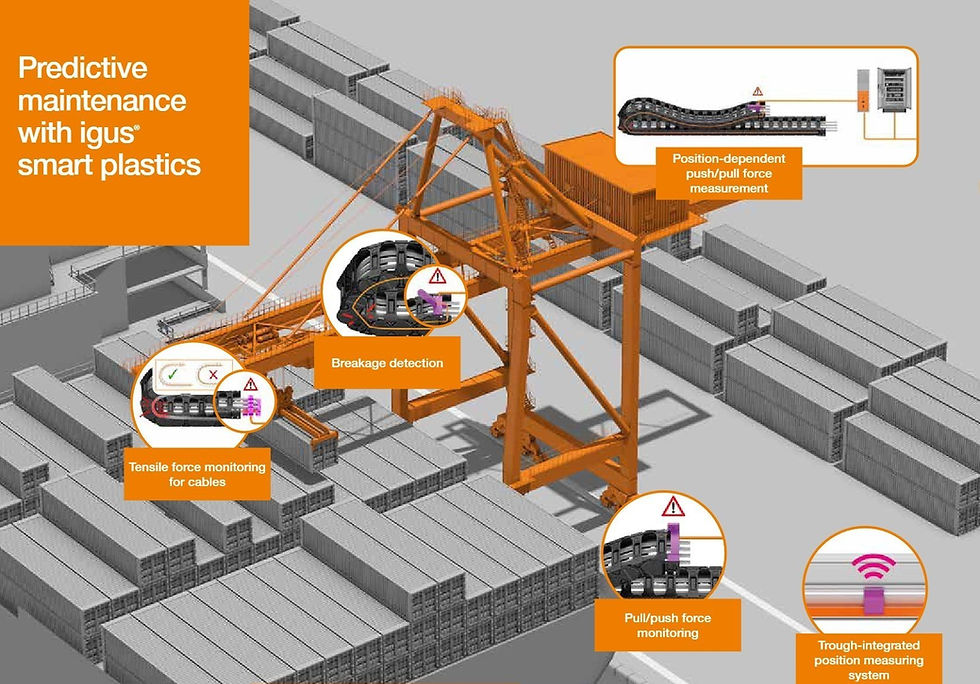

Smart Plastics with Condition Monitoring

igus integrates i.Sense and i.Cee systems for predictive maintenance. These systems monitor the wear and condition of energy chains, cables, and bearings in cranes and handling machinery, minimizing downtime by signaling when replacements or maintenance are needed.

Energy Chain Systems for Cable Management:

igus energy chains (e-chains®) are widely used in cranes, ensuring efficient cable guidance even in challenging environments. These systems can handle dynamic motion, extreme loads, and long travel distances, making them ideal for the high demands of crane automation. They also are made from lubrication free, low-maintenance materials, improving reliability in automated operations.

Gantries and Linear Motion Systems:

igus offers linear actuators, modular drylin® gantries, and motion systems that are increasingly adopted for automatic movement and positioning tasks within materials handling centers. These are specially designed for quiet, precise, and maintenance-free operation, ideal for conveyor systems and robotics integration.

Lubrication free Bearings and Components:

igus provides high-performance polymer bushings and bearings that eliminate the need for external lubrication, reducing maintenance time and costs. These components are critical in automated crane systems as they improve efficiency in pivoting movements.

Autonomous Cable Reeling Systems:

For cranes with long travel distances, igus has developed autonomous cable carriers and reels designed for power and data transmission. These systems ensure minimal resistance and wear during automated crane movement.

Custom Automation Solutions with Lightweight Components:

igus specializes in creating customized automation systems using lightweight polymer materials. This is beneficial in crane and materials handling operations where weight reduction aids in improving energy efficiency and speed.

Collaborative Systems Integration:

igus is actively collaborating with manufacturers and integrators in the crane and materials handling sectors to offer solutions that are compatible with Industry 4.0 and IoT-enabled systems.

Overall, igus®’s focus on maintenance free, durable, and lightweight polymer solutions aligns perfectly with the increasing demand for automation and smart systems in the crane and materials

handling industry. Our innovations are transforming traditional operations into highly efficient and cost-effective automated systems.

How has the adoption of automation impacted labor requirements and workforce skills in this industry? One of our slogans for our low-cost automation products is “If you hate it – automate it!” – the adoption of automation in the crane and materials handling industry has significantly minimized the need for repetitive, labor-intensive tasks.

By handling processes more efficiently and safely, reducing the demand for traditional roles in workplace safety could be improved, e.g. by removing workers from hazardous environments. There is an increased need for technicians, engineers, and analysts to operate, maintain, and program automated systems, such as IoT-enabled predictive maintenance tools and robotics. Workers must develop skills in mechatronics, programming, and system integration.

As automation replaces certain roles, companies must invest in training employees for specialized positions like system maintenance, automation design, and software development.

Benefits and Challenges

Can you provide a detailed example of a project where automation led to a significant reduction in operational costs? Industry 4.0 application examples & customer references with smart plastics What are the most common misconceptions about automation in the crane and materials handling industry?

Common misconceptions about automation in the crane and materials handling industry from a company perspective usually involve automation being too expensive. While initial costs may seem high, long-term savings are offset by reduced downtime, lower maintenance, and increased productivity. ROI is typically achieved in a few years.

Another common misconception is that maintenance becomes more complex. Predictive tools like igus’ i.Sense simplify maintenance, minimizing downtime and preventing costly breakdowns.

Some even fear that automation may reduce control when quite frankly the opposite is true. Operators not only maintain control, but with dashboards and monitoring tools they can gain deeper insights and improve decision-making.

Somewhat connected to the cost aspect is the notion that automation is only for large companies. While this of course holds some truth, igus provides scalable, modular solutions with our Low-Cost Automation product line.

Some even think that automation is all about the improvement of speed, while it is really a holistic approach to overall efficiency. It enhances safety, energy efficiency, cost management, and operational data insights.

How do you address concerns related to the reliability and maintenance of automated systems? Our system Superwise, for example, simplifies and automates maintenance through advanced monitoring and predictive maintenance technologies that enhance equipment reliability and reduce downtime. While the specifics of Superwise’s solutions may vary depending on the application, the following key principles illustrate how it addresses concerns related to automated processes.

Superwise integrates sensors into machines and systems to continuously monitor critical parameters like temperature, vibration, pressure, and wear. These sensors provide a constant stream of data, enabling automated tracking of machine conditions without the need for manual checks.

Superwise can analyze collected data to predict potential failures before they occur, by detecting anomalies and identifying trends in equipment performance. The system can automatically flag components showing signs of wear or decline. This enables maintenance to be scheduled proactively, preventing costly breakdowns and unplanned downtime.

Superwise can even be set up to order the replacement parts needed automatically so that they are available hassle free when needed.

igus and Automation

What roles do igus products play in enhancing the precision and reliability of crane systems? igus products play a vital role in improving the precision and reliability of crane systems through their tribologically optimized polymer-based solutions. Energy chains (e-chains®) ensure smooth and safe cable management, reducing tangling, vibration, and wear during crane operations. Made from durable polymers, these chains resist extreme weather conditions, UV exposure, and heavy loads, ensuring consistent power and data transfer over long periods with minimal maintenance.

As outlined before, our smart plastics enhance precision and reliability as well. Smart plastics currently include products like I. Sense e-chain systems, Chainflex® smart cables, iglidur® bearings with sensors, drylin® linear systems, and predictive maintenance modules like i.Cee. Each is designed to work independently or as part of a complete Industry 4.0 setup, enabling real-time monitoring and predictive maintenance that improves efficiency, reduces downtime, and prolongs operational

lifespan.

How does igus ensure the compatibility of its products with existing automation technologies? igus ensures the compatibility of its products with existing automation technologies through a combination of modular design, standardized interfaces, and advanced engineering innovations. By focusing on user-friendly integration and adaptability, igus makes products that seamlessly work with a wide range of automated systems and industrial setups.

Future Outlook

What emerging technologies do you believe will have the most significant impact on automation in the next 5-10 years? Emerging technologies such as smart sensors for predictive maintenance, artificial intelligence (AI), and the Industrial Internet of Things (IIoT) are poised to have the most significant impact on automation in the next 5–10 years. These technologies are reshaping the way industries approach efficiency, reliability, and scalability in automated systems.

How is igus preparing for the integration of AI and machine learning into its automation solutions? igus is strategically developing smart products that generate high-quality data for AI analysis, while working on proprietary AI solutions not only for our predictive maintenance systems. Of course, igus simultaneously invests in partnerships to align its products with AI-powered automation ecosystems.

Through these efforts, igus is not only preparing for the future of automation but is actively shaping it. With AI capabilities driving predictive maintenance, adaptability, and operational efficiency, igus is set to lead the integration of intelligent automation technologies across industries.

and strain relief.

What are the potential environmental benefits of increased automation in the crane and materials handling industry? Increased automation in the crane and materials handling industry offers a range of environmental benefits, stemming from improved energy efficiency, reduced waste, and optimized resource utilization. By integrating advanced technologies such as AI-driven systems, IoT-enabled monitoring, and smart sensors, automated solutions contribute not only to operational efficiency but also to more sustainable practices.

Closing Thoughts

How does igus plan to support its customers in navigating the transition to more automated systems? igus is committed to supporting its customers in navigating the transition to more automated systems by providing tailored solutions, comprehensive resources, and ongoing collaboration to ensure a smooth and effective integration of automation technologies. Whether in manufacturing, logistics, crane operation, or materials handling, igus focuses on empowering customers with reliable, cost-effective, and scalable automation tools.

-01.jpg)